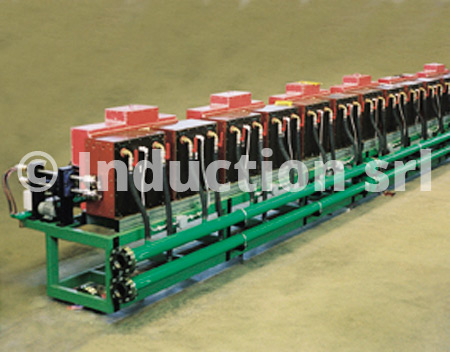

Automotive: Springs - Leaf Springs

Production lines for automotive parts are a consolidated product in Induction, as these allow the complex heating system to optimize end-of line mechanics by fully leveraging the properties and the potential of induction heating.

- Turn key lines for springs production

- Turn key lines for springs production

- Complete lines for spring productions

- Induction heating plant for stabilizer bars partial heating

- Metals hot & warm forming processes by induction heating

- Induction heating line for Hatebur presses

- 2000 kW plate induction heating line for leaf spring production

- 5 MW Tandem forging line for crankshafts production

- 2000 kW plate induction heating line for leaf spring production

- Complete line with mechanics for springs production

- Complete induction heating line for springs production

Centers Robotic

Increasingly common in the world of hot forging is the application of the robotics in order to obtain work-island completely automated. Our specific experiences in hot-working permit us to utilize and to apply different kind of robot or mechanical hand with extreme efficacy, despite of the prohibitive ambient conditions.

- Robotized induction heating plant for total and partial heating

- Robotized induction heating plant for total and partial heating

- Robotized induction heating plant for total and partial heating

- Robotized turn-key plants for metals hot forging

- Robotized induction heating line for automotive stabilizer bars hot forging

- Robotized induction heating line for stabilzer bars partial heating

- Robotized induction heating plant for partial heating

- Robotized turn-key line for induction partial heating and hot forging

- Robotized turn-key line for hot forging

Converters

Induction converters are medium and high frequency static generators, applied to resonant circuits, which allow heating through magnetic coupling. Induction’s experience leaded to the realization of series, parallel and L-L/C converters, according to the “state of the art” of technologies for induction heating. Continuous Research & Development activities leaded to totally digital converters, with the possibility of energy saving through Multi-System generators.

- Converters for induction heating equipment

- Converters for induction heating equipment

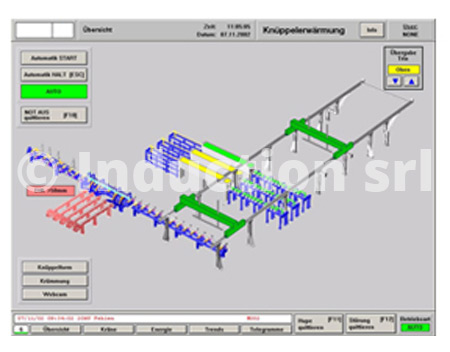

- Software design for induction heating plants

- 1000 kW Converter for induction heating equipment

- Medium frequency SCR inverter for induction heating equipment

- SCR Converters for induction heating

- 100 kW induction heating plant

- IGBT Converters for induction heating

- SCR Converters for induction heating

- SCR Converters for induction heating

- Induction converter and coils for tubes industry

Extrusion

With regards of the extrusion of steel, aluminum, brass and alloys the experience with Induction assures the supply of press machines with servomechanism having high quality standards and maximum production flexibility.

- Aluminum conic heating plant and subsequent extrusion

- Aluminum conic heating plant and subsequent extrusion

- Heating for pipe extrusion process

- Induction heating plant for metals hot extrusion

Melting

Induction melting furnaces find application in the areas of both ferrous and non-ferrous metals, as well as for precious metals.

- Induction furnaces for melting of steel and non-ferrous metals

- Induction furnaces for melting of steel and non-ferrous metals

- Induction melting at medium frequency process

- Induction melting plant complete with hydraulic tilting and ingots carosel

- Induction melting furnace with electric tilting

- Induction melting furnace “Roll-over” type

- Ingots production by induction melting process

- Induction melting furnace for laboratory

- Induction melting furnace “Roll-over”

- Induction melting plant

- Induction melting processes

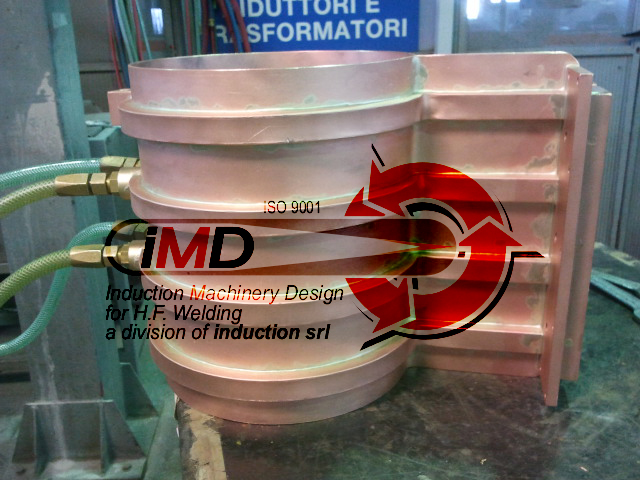

High Frequency Division

The iMD division of the INDUCTION s.r.l. Company offers to all those working in the field of welded metal pipe the best applications and services

- Design and construction of High Frequency output transformers

- Design and construction of High Frequency output transformers

- Solid State (SiC) and Triode Valve High Frequency Welders

- Heating coils and high frequency connections for High Frequency Welders

- Heating coils for High Frequency Welders

- High frequency connection for High Frequency Welders

- High frequency output transformer for High Frequency Welders

- Complete electronic cards set for high frequency welders control

Inductors

The inductors created by Induction guarantee the best performance regarding heating quality

- Seam annealing inductor and rolling shutter loader

- Seam annealing inductor and rolling shutter loader

- Induction converter and coils for tubes industry

- Inductor for tubes industry

- Heating coils for seam annealing plants

- Induction heating plants for elbows production

- Induction furnaces for melting of steel and non-ferrous metals

- Set of coils for tubes industry

- Induction heating plants for metals hot & warm forming

- Induction heating plants for metals hot & warm forming

- Heating coils for special applications

Kilobar - Melting of precious metals

The reliability, the speed and the accuracy, together with the high efficiency both from the electrical and metallurgical point of view allow to medium frequency melting process to be cheap, ecological and efficient

- Plant in controlled atmosphere for golden ingots production

- Plant in controlled atmosphere for golden ingots production

- Plant in controlled atmosphere for golden ingots production

- Induction melting furnace in controlled atmosphere for golden ingots production

- Induction melting furnaces for gold and precious metals

- Induction melting furnace with hydraulic tilting

- Induction melting furnace for precious and non-ferrous metals melting

- Converters type “MIGNON”

- Converters type “MIGNON”

Hot Rolling

The main advantage linked to the use of an induction furnace, in the different parts of the roll train, is temperature control for different materials and different dimensions

- Induction heating plants for hot rolling

- Induction heating plants for hot rolling

- 2.400 kW turn-key line for hot rolling

- 6 MW induction heating plant for stretch reducing of tubes

- 3000 kW plant for continuous flat strip heating and subsequent hot rolling

- Induction heating for high speed steel lamination

- Flat spring partial heating plant for parabolic hot rolling

- Rolling mill on induction heating line

- Induction heating plants for hot rolling mills

- Induction heating plants for hot rolling mills

- Heating in continuous for hot rolling processes

TURNKEY PLANTS

Induction Srl supplies COMPLETE TURNKEY LINES in the following sectors: – STEEL AND BRASS HOT FORGING – HOT BILLETS SHEARING LINES – BARS ROLLING COMPLETE LINES ROLLING BARS – HEAT TREATMENT COMPLETE LINES (hardening, tempering , annealing, normalizing) – ROBOTIZED WORKING ISLES

- 2.400 kW turn-key line for hot rolling

- 2.400 kW turn-key line for hot rolling

- Induction heating for high speed steel lamination

- Turn key lines for springs production

- Complete lines for spring productions

- Induction heating plants for hot rolling mills

- Induction heating plants for hot rolling mills

- Heating in continuous for hot rolling processes

- Robotized turn-key plants for metals hot forging

- Induction heating line for Hatebur presses

- 5 MW Tandem forging line for crankshafts production

Mechanics

Design and realization of all mechanics related to every type of induction heating plant:loading and unloading tables, automatic and semi-automatic loaders, introduction and extraction mechanics, piece’s handling mechanics and turn-key lines complete of related mechanics.

- 200 kW plant with billet loader for aluminum heating

- 200 kW plant with billet loader for aluminum heating

- 600 kW plant for steel forging with loader

- Seam annealing inductor and rolling shutter loader

- Induction heating plants with fast automatic inductors exchange

- Induction heating plant for metals hot forging with rolling shutter loader

- 5 MW Tandem forging line complete of mechanics

- Induction hot shearing complete line

- Induction hot shearing complete line

- Complete line with mechanics for springs production

- Complete lines with mechanics for spings production

Turn-key plants for elbows production

Turn-key plants for elbows production. Drastic reduction of turn on times either with a bare arbor or coated with a carbon steel pipe. Possibility to work with only one converter at different stations even with different power ratings.

- Induction heating plants for elbows production

- Induction heating plants for elbows production

- Induction heating turn-key plants for elbows production

- Elbow productions by induction heating plants

- Turn-key plants for elbows production

- Induction heating plants for elbows production

- Turn-key plants for elbows production

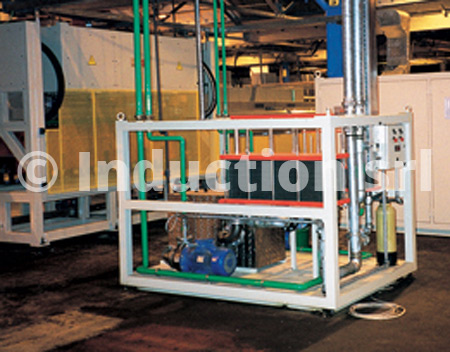

Cooling

Maintaining high quality standards with regards to this apparently insignificant detail makes Induction a solid industrial company respected at an international level.

- Extended heat exchanger group

- Extended heat exchanger group

- Extended heat exchanger group

- Converters and water cooling groups for induction heating applications

- Extended heat exchanger water cooling system

- Water cooling units for induction heating plants

- Water cooling group with heat exchangers and pumps for induction heating plant

- Water cooling units for induction heating plants

- Water cooling units for heat treatments plants

- Extended heat exchanger group

Tempering

Induction heating can also be applied for the thermal stabilization of the metallurgical structure of metals with different profiles, as well as for semi-finished products.

- Induction heating plant for heat treatments of tubes and pipes

- Induction heating plant for heat treatments of tubes and pipes

- Induction heating equipment for heat treatments of tubes and pipes

- Induction automatic annealing plant

- Induction heating plant for seam annealing of tubes

- Induction heating plant for heat treatments of tubes and pipes

- Induction heating equipment for heat treatments of tubes and pipes

- Complete line for induction heat treatments of tubes and bars

- Induction heat treatment line for pipes and tubes, with automatic loading form boundle and discharge table

Heating of Wires / Ropes

From the induction heating systems for wire, strands, ropes, strips and profiles, up to the multi-wires heating system, we offer our competence and technologies even in this important industrial sector.

Heating in controlled atmosphere

In line annealing plants in controlled atmosphere, applied in automatic lines for ferrous and non ferrous metals. Heating systems with non-combustion heat sources are used when there is the necessity to remove any surface oxidation or whether heating cycle performances in controlled atmosphere are needed.

- Plant in controlled atmosphere for golden ingots production

- Plant in controlled atmosphere for golden ingots production

- Induction heating equipments in controlled atmosphere

- Complete line for induction heating in controlled atmosphere

- Induction heating plants in controlled atmosphere

- Induction melting furnace in controlled atmosphere for golden ingots production

Coating

Induction’s experience is confirmed by the fact that we supply the largest companies of the sector in production plants all over the world

- Induction heating plant for heat treatments of tubes and pipes

- Induction heating plant for heat treatments of tubes and pipes

- Induction heating equipment for heat treatments of tubes and pipes

- 1.000 kW plant for ring extrusion coating

- Induction converter and coils for tubes industry

- Coating plant

- Induction heating for coating

- Induction heating plants for hot pipe forming

- Tubes coating process with induction heating plant

- Induction heating plant and set of coils for coating process

- Induction heating double converter plant for tubes industry

Integrated heating system for electric motors, hot driving and brazing

Induction heating represents a valid solution for hot assembly when coupling metal parts, since it allows to compensate interference with thermal expansion and subsequent driving with definitely smaller forces: productive results are significant.

- Integrated induction heating system for heating of rotors, complete of mechanics

- Integrated induction heating system for heating of rotors, complete of mechanics

- Induction heating of electrical motor parts for assembling

- Induction heating systems for assembling of electrical motors parts

- Integrated induction heating system for electric motors

- Heating for hot driving of rotors and mechanical parts

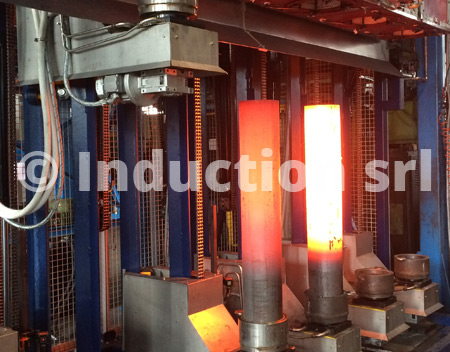

Hot Forging

Induction furnaces for hot forging of steel, brass and aluminium. Plants complete with automatic and semi automatic loading mechanics. Possibility of design and realization of special plants.

- 100 kW induction heating plant

- 100 kW induction heating plant

- 200 kW plant with billet loader for aluminum heating

- 600 kW plant for steel forging with loader

- 100 kW induction heating plant for metals hot forging

- Induction heating plant for metals hot forging

- 2.000 kW complete plant for steel hot forging

- 2000 kW induction heating plant for hot shearing line

- Partial heating plant with automatic workpiece loading and unloading

- Induction heating plants for metals hot forging

- Induction heating plant for stabilizer bars partial heating

Induction Heating Plants - Special Treatments

The use of induction heating for material treating is a consolidate procedure, both for the superficial hardening of metal parts or pipes, as well as for superficial treatments according to specific characteristics such as brassing, nitriding etc.

- Induction heating plant for heat treatments of tubes and pipes

- Induction heating plant for heat treatments of tubes and pipes

- Induction heating equipment for heat treatments of tubes and pipes

- Automatic lines for annealing of bars, wires, strands and pipes of ferrous and non-ferrous metals

- Hot treading heating plant

- 3000 kW plant for pipe hardening

- Plants for heat treatments

- 1.000 kW plant for reheating in a Properzi continuous casting line

- Induction heating automatic lines for annealing of bars, wires, strands and pipes of ferrous and non-ferrous metals

- Induction automatic annealing plant

- Induction heating plants for hot pipe forming