Three reasons to choose an INDUCTION® Heating Plant

Specific technical advice – Attention to detail – Support pre and post sales

The difference between a common induction heating plant and an Induction ® plant isn’t based only on our reliability and technology, but most of all on all related professional services that are supplied to each of our Customers. Starting from specific technical advice, to high-care in the realisation, up to the support during pre and post sales.

Qualified consulting in designing phase

Thanks to more than 30 years of experiences, our technical office is a high-quality partner for designing and definition of all technical characteristic related to a new production line. Through an accurate feasibility study, we offer to Customers the best solution related to their specific problems, correlated of a study of production costs and operating profitability of the plant, in order to optimize all choices during the designing phase.

High-efficiency induction heating plants

All Induction’s plants are constituted by frequency static converters, which supply heating inductors, designed and designed by ourselves.

The high electrical efficiency of our converters led to a high thermal efficiency of our systems, allowing us to a considerable reduction of energy consumption at same working conditions, in terms of production and temperature.

Through a modular construction of our converters and the application of high technology products, we obtained a great reliability even in worst and not optimal working conditions, simplifying even all related maintenance jobs.

Efficient after sales service

To guarantee a reliable and uninterrupted functioning of Induction’s plants, our technical service is reachable through a simple phone call.

The technical intervention will be accomplished by one of our on-field technician or, when it’s necessary, by one of our technician directly from our headquarter. By sending a technician within 24 hours or immediately through the remote assistance, we will guarantee to the Customer both the promptness and the professionalism of our services.

Induction® products for Induction Heating

MECHANICS for induction heating plants

Induction heating applications cover several fields and to all mechanical components could be requested high adaptability: our technical office designs and realizes loading and unloading devices (in continuous or intermittent operations), manipulation devices on more axis under the press, management of pieces on storage and loading tables, etc. etc.

AUTOMATION – Robots and 3D Vision

INDUCTION has recently successfully developed and installed a loading system fully automatized, as new and reliable alternative to the traditional mechanical loaders for the induction furnaces.

It’s constituted by an AUTOMATIC ROBOT which through a 3D VISION SYSTEM is able to run all the necessary operations for the loading of the billets to the induction furnace.

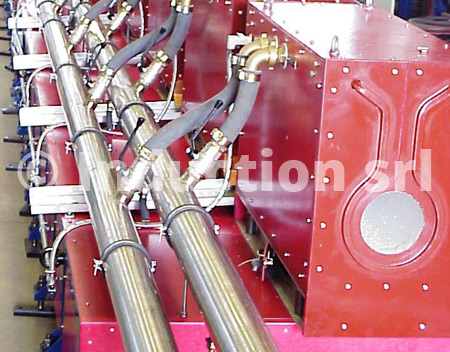

INDUCTORS for induction heating plants

All heating inductors realised by Induction guarantee the best heating quality according to project specifications.

Besides standard inductors, we can design and realize special inductors, according to your production and/or mechanical requirements.

CONVERTERS for induction heating plants

Induction converters are medium and high-frequency static generators, applied to resonant circuits, which allow heating through magnetic coupling. Induction’s experience led to the realization of series, parallel and L-L/C converters, according to the “state of the art” of technologies for induction heating. Continuous Research & Development activities led to totally digital converters, with the possibility of energy saving through Multi-System generators.

COOLING for induction heating plants

The electrothermal application is characterized principally by an extremely high heating power density per volume unit, compared to any other industrial process.

For this main reason, all Induction’s plants are equipped with an efficient cooling system in a closed loop, which allows obtaining an optimum thermal regime of all electronics and electric components.

TURN-KEY LINES

Induction supplies complete Induction Heating Plants and TURN-KEY LINES for following applications:

- Complete forging lines

- Hot metals shearing lines

- Hot rolling mill lines

- Complete lines for heat treatments (quenching, tempering, seamless annealing)

- Robotized lines