Project Description

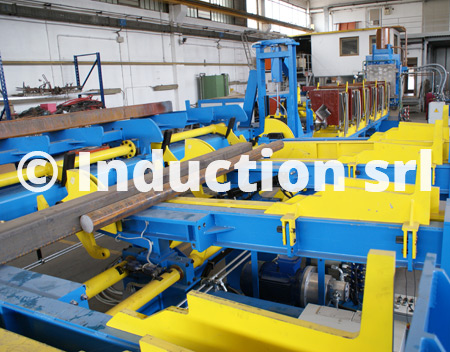

The mechanical component of Induction systems is usually an important component in the creation of an industrial level electro-thermal process of any type. Once the necessary automation is reached, the management of treated parts is often required, depending on the application or the heating method. The application of induction heating may cover the most diverse needs, so the mechanical components may be required for continuously or intermittently loading – unloading, for the management of part storage, etc. The heating system often requires mechanics that are extremely complex, even more than the electro-thermal component. The selection of the most appropriate mechanics for each application is always backed by specific know-how and experience. This makes Induction the ideal partner, as demonstrated by the numerous references that go from the steelworks sector, to forging, to superficial treating, to coating, etc. Induction’s experience always allows perfect integration between mechanics and the electro-thermal heating system, with consequent satisfaction of process specifications that often impose strong design constraints. Furthermore, it’s possible to integrate the initial offering with a wide range of accessories that increase the added value of the supply, helping to satisfy particular Customer needs, or supporting them in the use of an unknown technology.