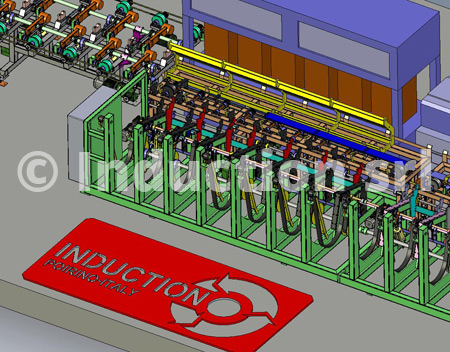

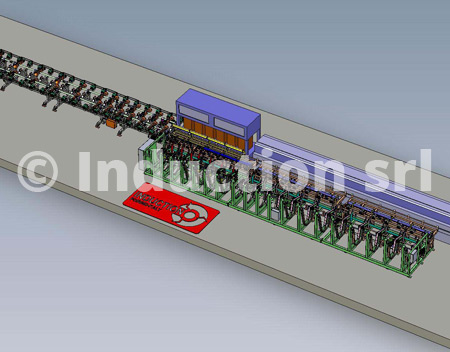

Project Description

Induction heating system integrates in workstations requiring a high automation for total control of the process. Induction Srl, thanks to multi decade experience in process developments with innovative solutions, in order to provide customer with support in obtaining quality products of excellence, cost- competitive, supplies COMPLETE TURNKEY LINES in the following sectors: – STEEL AND BRASS HOT FORGING – HOT BILLETS SHEARING LINES – BARS ROLLING COMPLETE LINES ROLLING BARRE – HEAT TREATMENT COMPLETE LINES (hardening, tempering , annealing, normalizing) – ROBOTIZED WORKING ISLES , complete with necessary automation to manage production of one or more automatic lines , also allowing remote control from a single point.